Returnable bottles

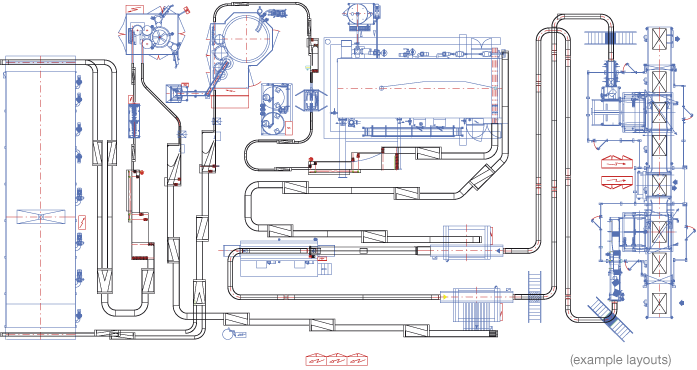

The bottling lines designed for returnable bottles are typically composed of crate depallettiser, de-crater, single or double end bottle washer, crate washer, various types of filling technologies, wet glue labelling, pasteurisation process and finally crate filling and crate palletising.

Depending on the specific requirements, other special equipment is included in the supply, such as new bottle depaletizing to integrate unreturned or damaged rejected bottles, sleeve labelling, de-capsulers, de-sleevers, screw cap removing and of course high quality inspection equipment for quality control.